Rajoo pioneered the non-woven fabric technology in India and supplied many spun bond lines in the last decade. Now introducing yet another non-woven fabric technology - Melt Blown.

FabrEX® nonwoven lines are designed and manufactured targeting various applications to provide specific functions such as absorbency, liquid repellence, resilience, stretch, softness, strength, flame retardant, washable, cushioning, filtering, use as a bacterial barrier and sterility. These properties are often combined to create fabrics suited for specific applications, while achieving a good balance between product use-life and cost. They mimic the appearance, texture and strength of a woven textile or polymer fabric and can be as bulky as the thickest padding. In combination with other materials they provide a spectrum of products with diverse properties, and are used alone or as components of apparel, home furnishings, health care, engineering, industrial and consumer goods.

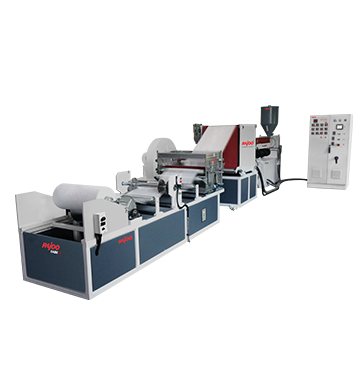

Spunbond lines

Rajoo pioneered developments in PP Non- Woven extrusion systems and emerged as the only Indian supplier with production capacity ranging from 200 to 500 kg/hr, weight range from 12 to 150 gsm, width range from 1600 to 3200mm.

Fabrex series of extrusion lines for producing nonwoven fabric consist of features like automatic screen changer, melt pump, spinnerets, filament cooling / fiber quenching, filament stretching / draw bench, web forming, thermal bonding, vacuum furnace / calciner, ultrasonic cleaner, touch screen control panel etc.

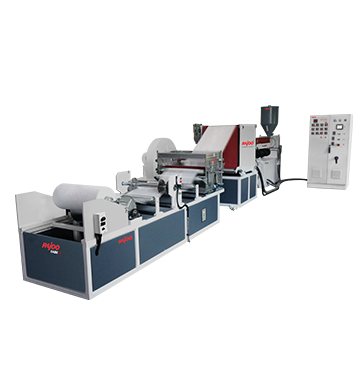

Melt blown lines

The continuous fibres produced by the single row melt blown process have a diameter below one micrometer. This makes them suitable for the production of highly demanding HEPA filters with H12 filtration efficiency.

Filaments from single row melt blown are stretched across the die width at precise temperature. The uniform stretching results in constant fibre quality over the entire material web.

Rajoo offers melt blown fabric making machine with max output of 35kg/hr with fabric width of 600 mm suitable for various applications.

Applications

Hygiene products

Baby and adult diapers: Top sheets, back sheets, ears, tapes, landing zone

Female hygiene: Top sheets, wings

Cleaning wipes: Baby care, cosmetics, etc.

Medical products

Surgeon's mask

N-95 masks/respirators

Disposable garments

Surgical drapes

Shoe covers

Home furnishing products

Beds: Mattresses, cushions, bed covers, disposal bedding

Seating: Upholstered backs, sub-panelling, intermediate layers

Technical products

Geotextiles: Erosion protection, filtration, reinforcement, drainage, separation layers, embankment fortification for streets, dikes, and farms

Structural engineering: Bitumen supports, roof insulation sheeting, diaphragms

Agriculture: Crop forcing nonwovens, insect protection

Automotive: Inner panelling, sound insulation, insulation

Packaging products

Envelopes

Tea bags

Clothes packaging