- About Us

- Vision & Mission

- The Chronicle of Rajoo Group

- Key Management

- Infrastructure

- Strategic Partners

- Global Presence

- Memberships

- Code of Conduct of Director

- Milestones

- Awards & Achievements

About Us

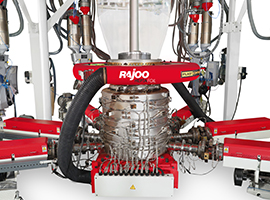

We are a leading manufacturer and exporter of Plastic Extrusion Machineries.

Rajoo Engineers Limited is a leading plastic extrusion machinery manufacturer in India and a trusted global exporter of advanced extrusion solutions. Founded in 1986 in Manavadar, Gujarat, Rajoo has grown into a globally respected name in plastic extrusion industry. With over 39 years of engineering excellence, innovation, and a customer-centric approach, Rajoo delivers high-performance plastic extrusion machines across 70+ countries.

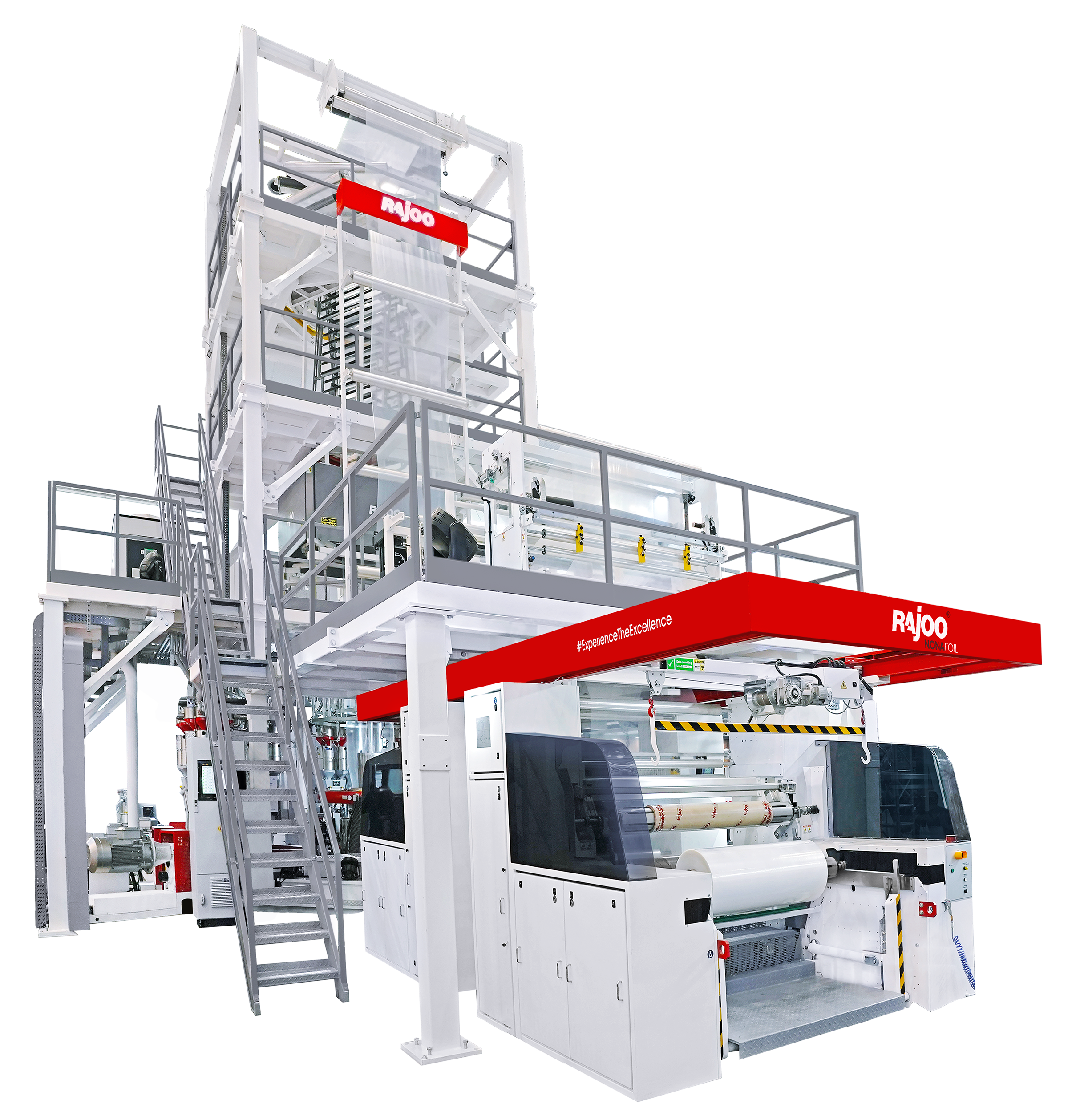

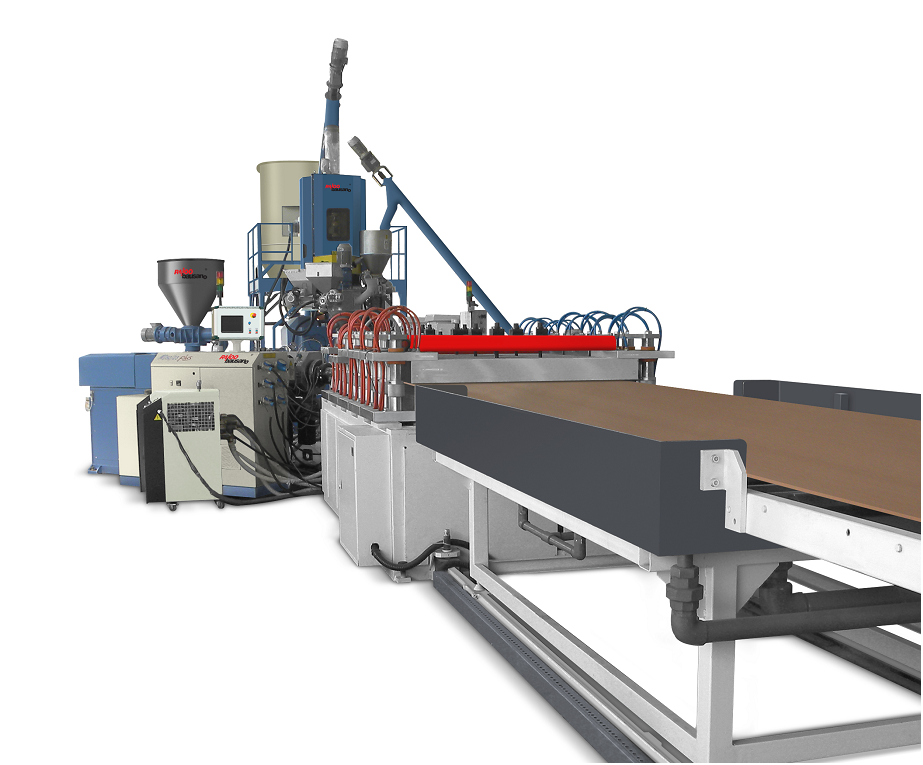

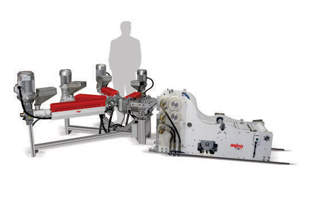

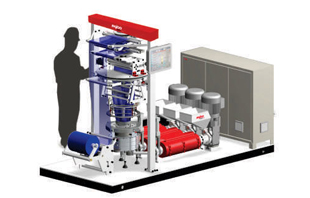

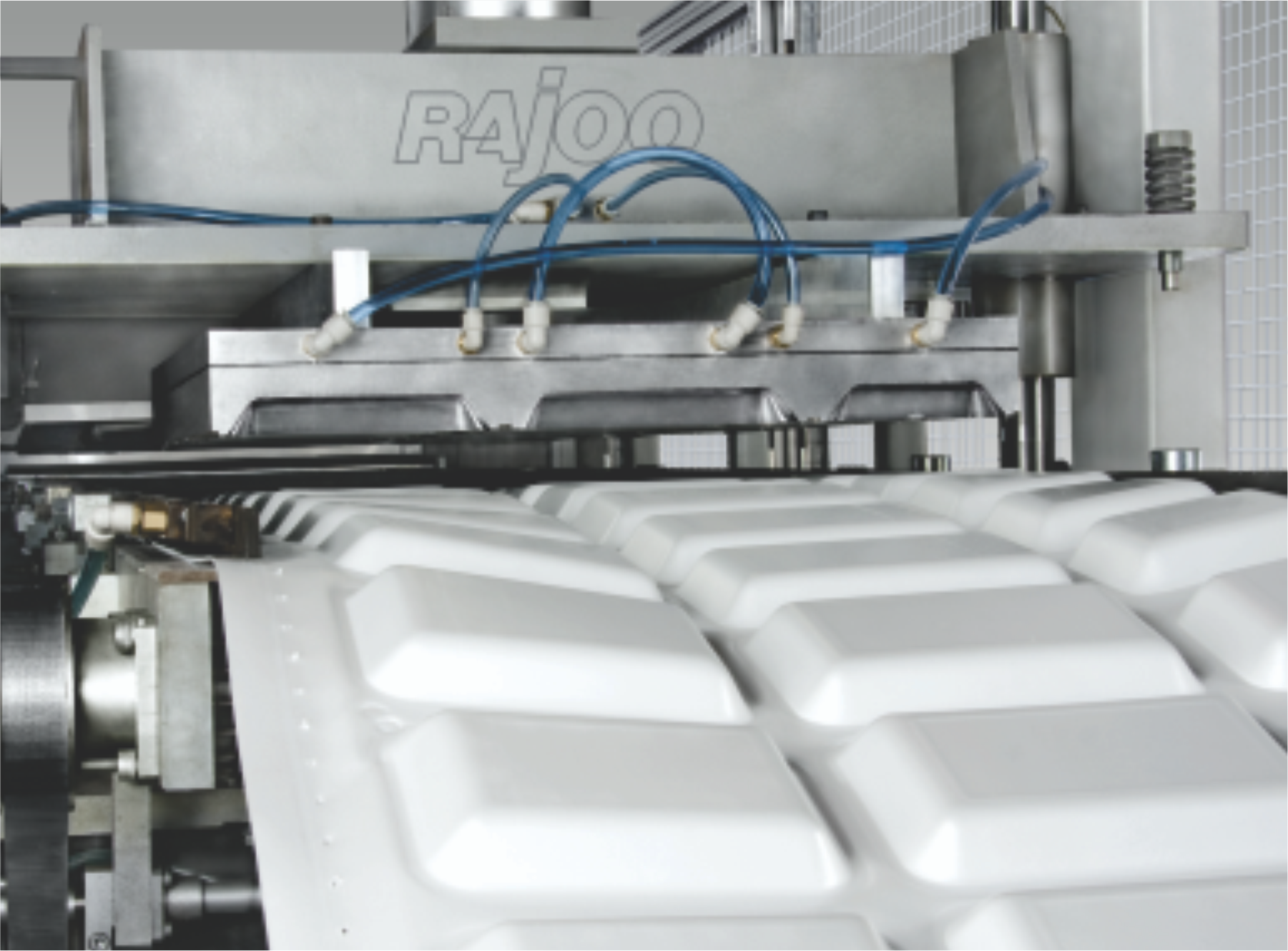

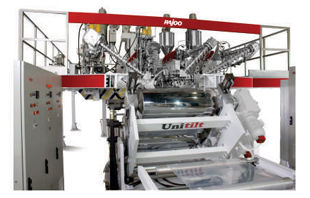

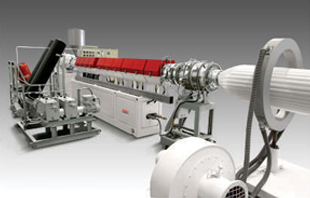

Rajoo is a market leader with more than 60% repeat business. Rajoo offers one of the industry's most comprehensive portfolios of plastic extrusion machinery, including mono and multilayer blown film lines (up to 11 layers), advanced sheet extrusion lines (up to 7 layers), multistation thermoforming machines, coating and lamination lines, cross-lamination film lines, and pipe plants with drip irrigation equipment, delivering end-to-end solutions for diverse plastic processing applications worldwide. These advanced extrusion systems are engineered to process a wide range of polymers such as LDPE, LLDPE, MDPE, HDPE, PP, EVA, and barrier materials like EVOH, Polyamide, and Surlyn, along with thermoformable polymers including PET, PS, and PP.

Looking Forward:

At Rajoo, change is the only constant. Our business approach is driven by continuously evolving market needs and the pursuit of the right combination of a diversified product mix to deliver solutions best suited to local and global applications. The spirit of innovation and adaptation remains central to Rajoo's growth journey.

The merger with Wonderpacks has created a combined entity that stands among the best in India and one of the few globally renowned suppliers of end-to-end thermoforming solutions. Further strengthening our position in plastic converting technology, Rajoo has taken a significant leap by acquiring a majority stake in Kohli Printing and Converting Machines Pvt. Ltd.

These strategic initiatives have resulted in growth far exceeding market trends, driven by value-for-money technology, indigenous solutions tailored to customer needs, and a credible organisation that values its customers, suppliers, employees, and stakeholders, all built on the enduring foundation of Excellence in Extrusion.

Vision & Mission

Our Vision

To become one of the most trusted and passionate solution providers for plastic extrusion machinery worldwide, in the best interest of all stakeholders, while consistently pursuing ethical business practices.

Our Mission

Excellence in Extrusion is our mission and our mindset. While it defines a clear direction for Rajoo, it also gives us the license to innovate because excellence has no static definition. It is relative, continually evolving, and inspires us to push boundaries in technology, quality, and performance every day.

Our Philosophy

Rooted in humble origins, Rajoo follows a philosophy of purposeful Spiritual Professionalism. We believe in continuous improvement, transparent dialogue, respect for human skills, and mastery of technology. This spirit shapes the professionalism that defines Rajoo and sets us apart as a values-driven engineering organisation.

The Chronicle of Rajoo Group

A Tree Called Rajoo

The germination of an idea nurtured by an ideology has resulted in creating one of the most respected and sought-after company in plastic extrusion Rajoo Engineers Limited.

The seed was sown in 1986 at a village named Manavadar, near Junagadh in the state of Gujarat, with the guiding vision of Mr. C. N. Doshi, the founder of Rajoo. A strong understanding of the market, desire to learn and a committed human capital created a strong foundation for this tree to blossom.

No sooner did the manufacturing operations commence, it was recognised as a player with a capacity to revolutionise the extrusion industry in India, so it did. Within a mere 4 years of commencement, the fruits of this tree had crossed the Indian shore to reach Africa, a salute to Indian manufacturing. Very quickly it was understood that to ensure a healthy performance, the soil's fertility needed to increase, and thus the group started investing in R&D at an early stage. Research relating to indigenous manufacturing, identifying and adapting technologies to suit local needs, lowering the cost of product and produce came into existence. Thus, began the journey from 'Performance for Purpose' to 'Excellence in Extrusion'.

The tree continued to blossom, from a dominant player in India to a respected and sought-after company across the globe, Rajoo was looked upon as a 'Responsible Global Organisation'. Within 8 years of establishment, came up the state-of-the-art manufacturing facility at Rajkot. Never before did the Asian plastic machinery manufacturing industry witness such stupendous response to an IPO as was witnessed during the Rajoo IPO an oversubscription by 24 times, clearly highlights the far reaching impact of this tree called 'Rajoo'.

The desire was strong to be recognised as a leader in the extrusion business; the intent was clear to be a responsible, ethical organisation; the commitments were firm adding value to customers, stakeholders and employees. As a result, the growth was exponential, beating market growth and trade forecasts. Today, presence in 70 countries; with 50% business from exports; 60% business from repeat customers are figures that speak volumes as the tree continues to blossom with fruits as growing revenues, growing human capital, growing product lines resulting in growing markets.

Wonderpack's merger with the companyto create a combined entity for 'end-to-end thermoforming solutions'; a JV (in Rajkot) with Bausano & Figli S.p.a of Italy, for revolutionising pipe manufacturing technology in India are all recent initiatives that would only further the shade of the tree.

Care for the environment, as a part of the Rajoo CSR initiatives, will only ensure that the grass is green on all sides.

Key Management

C. N. Doshi, Mentor - Guiding Light

Shri Chandrakant N. Doshi - A Doyen of the Indian Plastics Industry

A strong believer of the ethos of Indian manufacturing, he came with a dream, converted it into a conviction, fulfilled it and left us with his vision.

He started his career from State Bank of Saurashtra in a remote village of Gujarat - Manavadar, but was convinced that the ethos of Indian manufacturing alongwith the capabilities harbored by Rajoo would give rise to products that would be world-class, that too aiming at highly regulated European oriented markets. With the success that he met, the world started taking cognizance of Rajoo Engineers, as a company on a mission.

R. N. Doshi, Chairman

Mr. R. N. Doshi, co-founder of the Rajoo Group, is very hands-on and responsible for the overall operations of the Group. He comes with over 2 decades of experience in plastic processing, machinery manufacturing and product developments. His astute identification of new technologies and the novel paradigm to control cost without compromise are responsible for the sustained technology and business edge enjoyed by the group. Project execution remains a strong forte of Mr. R. N. Doshi.

Khushboo Chandrakant Doshi, Managing Director

Khushboo Chandrakant Doshi, a second generation entrepreneur, joined Rajoo Engineers in 2007 as Head of Marketing and Communications. She is an architect by education and holds a Master's Degree in Industrial Product Design from UK. She is also a Masters in Management for Entrepreneurs from IIM, Ahmedabad and Family Businesses from IIM Bangalore. Khushboo has cross functional expertise in marketing, corporate branding, PR and Communications strategy. As Product Manager of Rajoo's foam business, she was responsible for introducing this concept for the Company and co- ordinating with the collaborators . At Rajoo, she is also responsible for human capital management, financial management and most important - after-sales-service. As Director of the Company, Khushboo is an integral part of the senior management that is leading the company in the next phase of expansion in the global market.

Utsav Doshi - JT. Managing Director

Utsav Doshi, a second generation entrepreneur, joined Rajoo Engineers in 2011 as an Engineer Vendor Development. He holds a Bachelor's Degree in Mechanical Engineering with a Masters in Polymer technology from HTW Aalen University, Germany. Utsav has cross functional expertise in Design and Operations. Utsav is an integral part of the senior management and responsible for entire manufacturing activity at REL.

Utsav Doshi has technical experience to convert market requirements into technical layout, and having thorough knowledge in manufacturing and Plastic Processing.

Sunil Jain, President and Executive Director

With over 40 years of experience in plastics and packaging, Mr. Sunil Jain, President & Executive Director of Rajoo Engineers Ltd., has been instrumental in the company's global success. A Mechanical Engineering graduate from BITS Pilani in India, he oversees marketing, business development, and strategic initiatives. Mr. Jain's adept leadership has propelled Rajoo's presence both locally and internationally. Specializing in plastic extrusion machinery, he is recognized for fostering strong relationships with clients and partners. He represents Rajoo as a Director on the Board of Plastics Machinery Manufacturers Association of India ( PMMAI). His recent appointment as Chairman of the Indian Institute of Packaging ( an autonomous body under Ministry of Commerce, Government of India) further highlights the credibility and recognition of brand Rajoo. As he continues to lead Rajoo and the IIP, Mr. Jain is poised to drive innovation and strategic growth, cementing his role as a dynamic leader in the plastics and packaging sector.

Jinesh Shah - CSO

Jinesh Shah holds a Bachelors in Polymer Engineering & Post Graduated in Business Development.

Jinesh has strong expertise in marketing and sales of capital goods with a proven track record of building strong sustainable business relationships backed by 17 years of experience in the plastics industry. Jinesh is responsible for leading a variety of strategic efforts at Rajoo Engineers including playing a pivotal role in establishing company’s short, medium and long-term plans.

Jinesh also serves as a key member of NPD ( New Product Development) advisory committee and is a key contributor to technical research and development of extrusion process and applications.

Chintan B. Malkan - CFO

Chintan B. Malkan is the Chief Financial Officer (CFO) of Rajoo Engineers Limited, bringing with him over two decades of experience in finance, accounts, taxation, and commercial operations and has been an integral part of Rajoo Engineers for more than 17 years. His deep understanding of the company’s operations, coupled with his financial expertise, has played a pivotal role in streamlining processes, implementing SAP systems, and strengthening internal controls.

Chintan plays a key role in evaluating investment opportunities, optimizing capital structure, and supporting business expansion plans. With a strong focus on data-driven decision-making and financial discipline, he ensures that the finance function adds value across all areas of the business. Chintan is widely respected for his integrity, transparency, and ethical approach to financial management—qualities that have earned him the trust of senior leadership, colleagues, auditors, and stakeholders alike. He has consistently supported strategic decision-making through sound financial planning and compliance, while leading initiatives in tax optimization, cost control, and team development.

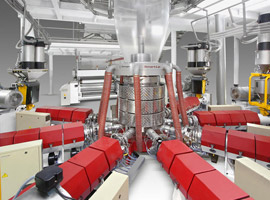

Infrastructure

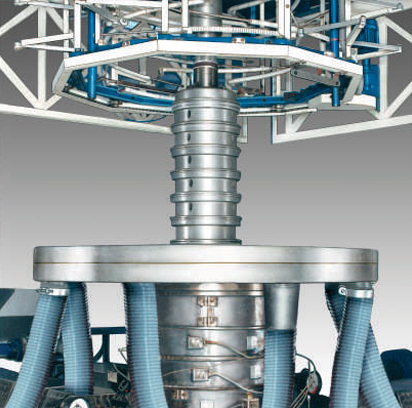

World Class Integrated Facilities

Rajoo's state-of-the-art design and manufacturing facilities in sprawling green acres and built-up area of 20,000 sq. mts. are located on the outskirts of Rajkot, Gujarat, one of the most industrious and vibrant states of India, famous for its engineering skills. World-class integrated facilities comprise design office, tool-room, die shop, metal treatment shop, fabrication shop, paint shop, assembly shop and testing shop.

Highly Qualified Team

The Company employs over 350 dedicated and motivated employees including 50 qualified engineers from various disciplines. The highly qualified and experienced engineers are at the core of the Research and Development department. The Company's Production, Marketing, Customer Care and Purchase departments are looked after by technocrats. The other commercial functions are manned by professionals of higher caliber and qualifications.

Advanced Process Analysis and Customization

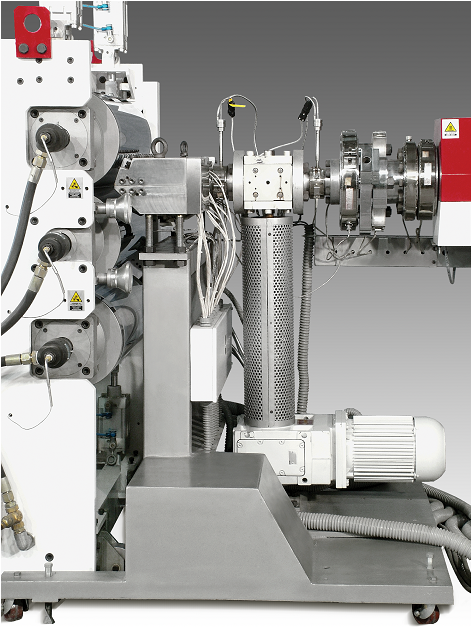

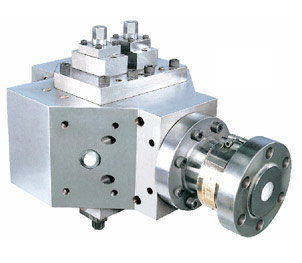

Advanced process analysis and simulation software (Flow 2000) for customizing screw and die spiral channel designs based on rheology of specific polymers are employed. IDEAS and UNIGRAPHICS software tools are also used for product engineering and simulation.

Shree Yantralaya a tool room

The state-of-the-art tooling zone, Shree Yantralaya goes a long way in ensuring consistently higher accuracy levels in all critical components. Enhanced quality components produced in a controlled air conditioned and dust free environment, with better workmanship, accuracy and quick turnaround are attributes that necessitated this significant investment in Shree Yantralaya which is now the abode for machine tools such as:

- Feeler, Taiwan 4 axis CNC Turning Centre

- Jyoti, India CNC Turning Centre

- Huron France 4 axis Double Column Vertical Machining Centre

- Jyoti, India 4 axis Double column vertical machining centre

- Huron, France Three Axis High Speed Milling Centre

- Heckert CNC Thread Milling Machine

- Jyoti, India Three Axis Vertical Milling machining centre

- You Ji, Taiwan 4 axis CNC Vertical Turning Lathe

- Dardi, China 3 axis water jet cutting machine

- Smithson, India Universal Cylindrical grinding machine

- DMG Mori 160 FD, Germany 5 axis machining center

- DMG Mori 80P, Germany 5 axis machining center

- DMG Mori CTX 1250 Gamma, Germany 5 axis machining center

- Saporiti Plus 400, Italy 5 axis thread milling machine

- Pinnacle, India CNC Surface grinding machine

These machine tools employs precise machining technology to produce extremely high-quality components. Digitally designed complex component are seamlessly transposed to these machine tools directly, eliminating the need for human intervention and related errors.

Shree Yantralaya presents an immaculate approach helping the company refine the scope of Excellence in Extrusion. Access to these latest machining technologies and techniques empowers the company to only further the customer satisfaction to greater heights. Ninety percent of the hot parts and air ring components of the machines built by Rajoo are now CNC machined resulting in higher repeat accuracy, quick turn around time and easy replaceability of components.

Shree Yantralaya (Dust free & Air conditioned)

- DMU80P duo Block 5-Axis Champion DMG Mori, Japan - X800 , Y1050, Z850, B180, C360

- SAPORITY PLUS 400 X 6000 5AXIS CNC THREADER MACHINE Sapority , Italy - X400, Y160, Z6000, B40

Most Advanced Machine Tools and Operational Techniques

To ensure that the products consistently live up to and in fact, surpass, the performance standards, Rajoo uses the most advanced machine tools and operational techniques available worldwide. Engineering and manufacturing departments are integrated through a digital network to ensure consistency, reliability and system. Like grooved feed bushes, barrels, screws, specialty mixing pins, die components, various kinds of spirals and air-rings are manufactured in-house. Plants with sound engineering basics are built with sculptor s precision, which is accomplished through self-sufficient tool room comprising of CNC Thread Milling Machine, 4-axis vertical machining center, deep hole boring machine, a horizontal honing machine, a gas nitriding furnace and hard chrome plating shop with stringent quality assurance test.

In-house Modern Paint Shop

The in-house modern paint shop facility is the first of its kind in the Asian industry. An amply dimensioned shot blasting room and baking oven ensures long life of paint and improves machine aesthetics.

Huge and Well-Equipped Assembly Shop

The huge and well equipped 3 different assembly shops are partitioned to accommodate machines of different heights and lengths. Highly skilled craftsman, having experience of more than 25 years, assemble the lines. The machines are tested thoroughly and performance is checked according to customer's specifications before dispatch. The testing bay is capable of accommodating several multilayer blown film lines at a time.

Ensuring Quality Through Various Processes

The strong integration with polymer suppliers and processors allows the choice of most suitable line for the customer's requirement. Various components and assemblies are designed using various computer simulations ensuring quality of the component with stage wise inspection of the components and assemblies using precision inspection tools, jigs and fixtures.

Ambiance

To provide a pleasant and hazard-free working environment, with adequate facilities and welfare arrangements, company has successfully completed a Green Field project in approx 20,000 Sq.mt. of area to convert the concrete jungle with old buildings into soft landscaping and lush green gardens for increasing work efficiency of its employees. Also effectively employed renewable energy resources such as solar light and rain water harvesting throughout Rajoo's premises. A huge cafeteria with capacity of 130 employees at a time with recreation room is providing stress free working environment to employees.

Infrastructure Gallery

Strategic Partners

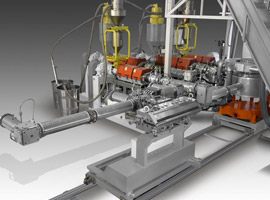

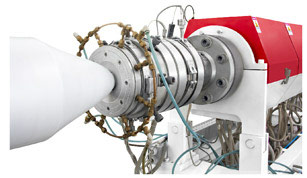

Bausano & Figli, Italy

Rajoo entered into a Joint Venture with Bausano & Figli, Italy which brought the formation of Rajoo Bausano Extrusion Pvt. Ltd on 26th October 2011. Rajoo successfully capitalized the technology loophole for effective production of PVC pipes and profiles in India. This collaboration will bring indigenous raw material from Bausano & Figli to India which will then take its final shape at the expansive infrastructure of Rajoo Bausano Extrusion Pvt. Ltd- should be brings critical assemblies

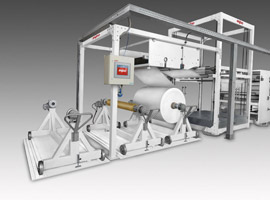

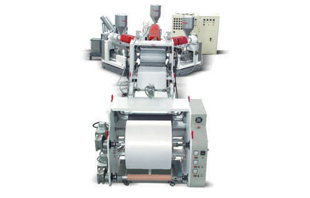

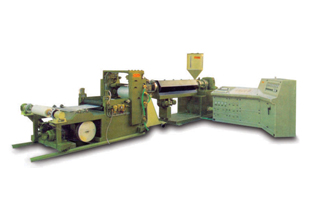

Kohli Industries

With the objective to change the market dynamics for Extrusion Coating and Lamination Machines, Rajoo Engineers joined hands with Kohli Industries. Kohli Industries comes with an experience of more than 47 years playing a leading role in the world to manufacture: Rotogravure Printing Presses, Solvent and Solvent-less & Combi Lamination Machines, Slitter Rewinders and Inspection Winders. With the ability to offer efficient and well-designed machines as well as an emphasis on customer care, Kohli has witnessed exponential growth. As of 2018, Kohli has successfully installed more than 1500 machines in over 30 countries.

This alliance will provide unparalleled expertise, technology and service to the flexible packaging industry.

Global Presence

World - The Marketplace

It took a mere 48 months since inception for Rajoo to flap its wings and create a flutter in the global plastic extrusion machinery market. This journey began in Africa in 1990 and today, over 70 countries have benefitted using the Rajoo solutions making India proud.

High in quality and still higher on value for money, the machines from Rajoo come with the stringent CE marking, go through stringent quality checks as per the global industry standards as well as the rigorous in-house protocols developed and perfected over the last decades.

The growing bright red Rajoo Spots dot the world map, clearly signaling the wide and growing acceptance of the brand Rajoo world over. Repeat customers are always considered as the most valid indicator for customer satisfaction. For Rajoo close to 50 % of its business in India and overseas comesfrom existing customers a significant endorsement to its product, technology, quality, price, support and business processes. A staggering 50% of its business comes from exports.

With every installation important and every market an opportunity, but supply to the developed and stringent markets of Germany, U.K. and U.S.A. has propelled Rajoo in the global league of quality manufacturers of extrusion machinery.a salute to the ethos of quality Indian manufacturing.

Algeria

Algeria  angola

angola argentina

argentina bangladesh

bangladesh botswana

botswana burma

burma colombia

colombia Congo

Congo ecuador

ecuador egypt

egypt estonia

estonia germany

germany ghana

ghana guatemala

guatemala hongkong

hongkong

indonesia

indonesia israel

israel italy

italy iran

iran japan

japan jordan

jordan kenya

kenya kuwait

kuwait latvia

latvia lesotho

lesotho liberia

liberia malawi

malawi malaysia

malaysia mexico

mexico namibia

namibia

nepal

nepal nigeria

nigeria oman

oman pakistan

pakistan papua new guinea

papua new guinea poland

poland portugal

portugal qatar

qatar saudi arabia

saudi arabia senegal

senegal singapore

singapore south africa

south africa spain

spain srilanka

srilanka zambia

zambia

sudan

sudan  syria

syria  tanzania

tanzania thailand

thailand tunisia

tunisia turkey

turkey Ukraine

Ukraine UAE

UAE uganda

uganda united kingdom

united kingdom united states

united states venezuela

venezuela vietnam

vietnam yemen

yemen india

india

Memberships

Name of the Organisation/Institute/Industry |

Abbreviation |

School of Packaging & Packaging Technology Center |

SIES |

All India Plastic Industries Association |

AIPIA |

All India Plastic Manufacturer's Association |

AIPMA |

Andhra Pradesh Plastics Manufacturer's Association |

APPMA |

Engineering Export Promotion Council |

EEPC |

Flexible Packaging Entrepreneur's Welfare Association |

FPEWA |

Gujarat State Plastics Mfrs.Association |

GSPMA |

Indian Machine Tool Manufacturers'Association |

IMTMA |

Indian Plastics Federation |

IPF |

Institute of Packaging Machinery Manufactuers of India(IPMMI) |

IPMMI |

Organization Of Plastics Processors of India |

OPPI |

Plastic Machinery Manufacturers' Association of India |

PMMAI |

Plastic Manufacturers' Association Rajasthan |

PMAR |

Plastic Manufacturers'Association Madurai |

PMAM-PLASMA |

Plastindia Foundation |

|

Rajkot Chamber of Commerce |

RCC |

Saurashtra Plastics Manufacturer's Association |

SPMA |

Shapar- Veraval Industrial Association |

|

Society of Plastics Engineers |

SPE |

Tamil Nadu Plastics Manufacturers' Association |

TPMA |

Rajkot Chamber of Commerce and Industry |

RCCI |

Rajkot Plastic Association |

RPA |

Code of Conduct of Director

Terms of appointment of Independent Director of Rajoo Engineers Limited (the Company)

I am pleased to inform you that the Nomination and Remuneration Committee and the Board of Directors of the Company (the Board), have appointed you as a Non-Executive Independent Director (NE-ID) of the Company effective ..........., in terms of the approval of shareholders, at the Annual General Meeting held on .............. and the applicable provisions of the Companies Act 2013 (the Act 2013) and the Listing Agreement with the Stock Exchanges.

Terms of office:

- The term of your Independent Director (ID) is for a period of five consecutive years, from the conclusion of the annual general meeting held on ............., subject to the provisions of the Companies Act, 2013 and the Articles of Association of the Company, as amended, from time to time, particularly regarding appointment, fees, expenses, retirement, disqualification and removal of directors;

- You are aware that no person shall hold office as a Director, including alternate Directorship, in more than 20 companies at the same time; Provided that the maximum number of public companies in which a person can be appointed as adirector shall not exceed 10. We hope that this appointment will be within these limits;

- You can serve for not more than two terms of consecutive five years each on the Board and before your second term commences, the Company will have to seek approval of the shareholders by way of a special resolution, on the expiry of the first term of five consecutive years;

- You can serve for not more than two terms of consecutive five years each on the Board and before your second term commences, the Company will have to seek approval of the shareholders by way of a special resolution, on the expiry of the first term of five consecutive years;

- This directorship is not subject to retirement by rotation during the term, as per the relevant provisions of the Act 2013;

- In case, you may have to resign your directorship in the Company for any reason or pursuant to any of the provisions of the Act 2013 or any of the applicable Law or the Articles of Association of the Company or you may be required to vacate the office of directorship, it can be done at any time by you giving a letter of resignation. While forwarding your intention to resign or not to seek re-appointment, it will be preferable if you give the Chairman reasonable time so that the Company can plan suitable succession to the Board;

- The performance of an ID will be reviewed during his tenure with the Company, in accordance with the processes agreed by the board, from time to time and you will participate in such reviews.

Milestones

- 2024

- 2023

- 2021

- 2020

- 2019

- 2018

- 2016

- 2015

- 2014

- 2013

- 2012

- 2011

- 2010

- 2009

- 2008

- 2007

- 2006

- 2005

- 2004

- 2003

- 2002

- 2001

- 2000

- 1999

- 1998

- 1997

- 1996

- 1995

- 1994

- 1992

- 1991

- 1990

- 1989

- 1988

- 1986

-

2024 Launched India's first Nonafoil- Nine-layer blown film extrusion plant at Plastfocus-2024, with a remarkable 350 kg/hr output

The PENTAFOIL-POD-AX is a testament to India's manufacturing prowess and our dedication to fostering indigenous technological ancements.

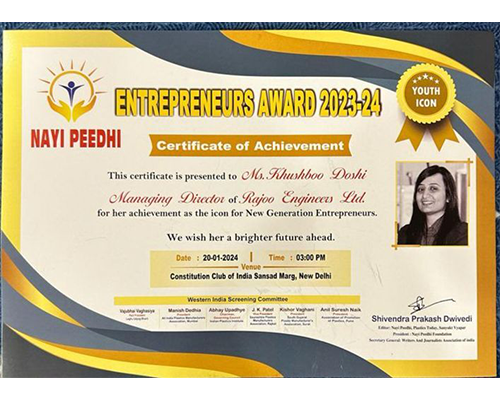

The PENTAFOIL-POD-AX is a testament to India's manufacturing prowess and our dedication to fostering indigenous technological ancements. Ms. Khushboo Doshi, Managing Director - Rajoo Engineers Limited has been awarded "Nayee Pidhi Entreneure Award 2023-24" for her achievement as the icon for the new generation entrepreneur

Ms. Khushboo Doshi, Managing Director - Rajoo Engineers Limited has been awarded "Nayee Pidhi Entreneure Award 2023-24" for her achievement as the icon for the new generation entrepreneur Our Company had unveiled the PROEX Series of High performance blown film line in an exclusive Product Premier held at M/s Balaji Multiflex Pvt. Ltd, Rajkot

Our Company had unveiled the PROEX Series of High performance blown film line in an exclusive Product Premier held at M/s Balaji Multiflex Pvt. Ltd, Rajkot -

Ms. Khushboo Chandrakant Doshi, Managing Director of the Company has been awarded the “Women Entrepreneur of the Year Award – Manufacturing Sector at the India SME Excellence Awards.

Launched of “LAMINA –E” - India's First Mono & Multi-Layer EVA/POE Sheet Line for producing encapsulant sheets for solar cells

Launched of “LAMINA –E” - India's First Mono & Multi-Layer EVA/POE Sheet Line for producing encapsulant sheets for solar cells Rajoo Engineers organized an in-person open house to launch their new product - PentaFoil® - POD - the new generation 5 layer blown film line

Rajoo Engineers organized an in-person open house to launch their new product - PentaFoil® - POD - the new generation 5 layer blown film line -

First time in India , LAMEX - Extrusion Coating & Lamination line running at 350 mt /hr was showcased live from our customer M/s Balaji Multiflex Pvt. Ltd -Rajkot on July 29, 2021

First time in India , LAMEX - Extrusion Coating & Lamination line running at 350 mt /hr was showcased live from our customer M/s Balaji Multiflex Pvt. Ltd -Rajkot on July 29, 2021 Introduced LAMEX-R series of extrusion coating and lamination lines for the raffia industry are designed for absolute ease of operation and high quality coating on flat / tubular HDPE / PP woven fabric with suitable back to back print registration control and are available in a host of configurations to suit individual customer's requirements.

Introduced LAMEX-R series of extrusion coating and lamination lines for the raffia industry are designed for absolute ease of operation and high quality coating on flat / tubular HDPE / PP woven fabric with suitable back to back print registration control and are available in a host of configurations to suit individual customer's requirements. -

Introduced FABREX – Melt Blown Fabric Making Machine

Introduced FABREX – Melt Blown Fabric Making Machine Launched MASCON - Automatic N-95 Mask Making Machine to produce various types of Masks like N 95 (with valve & without valve).

Launched MASCON - Automatic N-95 Mask Making Machine to produce various types of Masks like N 95 (with valve & without valve). -

Joined hands with Kohli Industries to create a formidable alliance to build and maintain one of the most advanced and versatile Extrusion Coating and Lamination machines. Also appointed Multigraph for promoting these machines pan India.

Joined hands with Kohli Industries to create a formidable alliance to build and maintain one of the most advanced and versatile Extrusion Coating and Lamination machines. Also appointed Multigraph for promoting these machines pan India. -

Launch a skill development hub Rajoo Innovation Centre for the plastics extrusion industry (a first in Asia)

Launch a skill development hub Rajoo Innovation Centre for the plastics extrusion industry (a first in Asia)  Launched HEPTAFOIL - Seven Layer Co-extruded Blown Film Line in Plast India-2018 and demonstrated through Virtual Reality(VR)

Launched HEPTAFOIL - Seven Layer Co-extruded Blown Film Line in Plast India-2018 and demonstrated through Virtual Reality(VR) Launched Lamex Extrusion Coating & Lamination Line to meet the needs of the flexible packaging industry

Launched Lamex Extrusion Coating & Lamination Line to meet the needs of the flexible packaging industry -

Introduced PENTAFOIL five layer POD blown film line to re-define application segments and demonstrated live @ K-2016

Introduced PENTAFOIL five layer POD blown film line to re-define application segments and demonstrated live @ K-2016 -

Launched Asia's first ever WPC line with 70% sawdust processibility

Developed Asia's first ever and Rajoo's 21st five layer blown film line with elevated air ring and displaying at PlastIndia

Developed Asia's first ever and Rajoo's 21st five layer blown film line with elevated air ring and displaying at PlastIndia Launched Asia's first ever most highest output sheet extrusion system amongst its class of lines & displaying at PlastIndia

Launched Asia's first ever most highest output sheet extrusion system amongst its class of lines & displaying at PlastIndia Launched tilting mould theromoformer with stacking, counting and packing solution, christened DISPOTILT

Launched tilting mould theromoformer with stacking, counting and packing solution, christened DISPOTILT -

Launched Two extruder three layer blown film line to meet highly competitive market of bag making,

christened MULTIFOILLite

Launched Two extruder three layer blown film line to meet highly competitive market of bag making,

christened MULTIFOILLite Launched Drip irrigation pipe plant for flat dripper and became India's largest supplier

Launched Drip irrigation pipe plant for flat dripper and became India's largest supplier -

India's first ever live demonstrations of cPVC Twin screw pipe plant with 250 kg/hr having pipe OD ranging from 250 - 500mm, christened

India's first ever live demonstrations of cPVC Twin screw pipe plant with 250 kg/hr having pipe OD ranging from 250 - 500mm, christened

Our Mentor

Mr. C N Doshi awarded

1. With Life time Achievement Award in recognition of his contribution to the innovation in plastics processing machinery segment and to the global plastic fraternity

2. For Excellent contribution to polymer industry in recognition of his outstanding contribution to plastics machinery industry by IPI Developed Asia's first ever smallest 5 layer sheet line, displayed at K, Germany & awarded by IPMMI

Developed Asia's first ever smallest 5 layer sheet line, displayed at K, Germany & awarded by IPMMI Exported India's first ever twin screw PVC pipe Plant, OD ranging from 250-500mm; with Maximum Output 1100kg/hr to Malawi

Exported India's first ever twin screw PVC pipe Plant, OD ranging from 250-500mm; with Maximum Output 1100kg/hr to Malawi -

Launched Drip irrigation pipe plant for round dripper, christened DRIPEX

Launched Drip irrigation pipe plant for round dripper, christened DRIPEX Developed Asia's first ever 65mm sheetline extruder for 180kg/hr output

Developed Asia's first ever 65mm sheetline extruder for 180kg/hr output Developed world's first smallest 3 layer blown film line, christened LABEX

Developed world's first smallest 3 layer blown film line, christened LABEX Launched and displayed first ever fully automatic Hybrid 5 layer blown film and displayed at Pastindia

Launched and displayed first ever fully automatic Hybrid 5 layer blown film and displayed at Pastindia Developed CSD ( Cylindrical Spiral Die) die head with rheologically optimized melt flow path for blown film line

Developed CSD ( Cylindrical Spiral Die) die head with rheologically optimized melt flow path for blown film line -

Supplied Asia's First CE Compliance 7 Layer Fully Automatic Blown Film Line to Turkey

Supplied Asia's First CE Compliance 7 Layer Fully Automatic Blown Film Line to Turkey Developed India's first ever PP non woven fabric making machine christened FABREX

Developed India's first ever PP non woven fabric making machine christened FABREX -

Wonderpack Merger : A Unified Approach for the benefit of the thermoforming Industry

Wonderpack Merger : A Unified Approach for the benefit of the thermoforming Industry Rajoo Engineers JV with Bausano of Italy : plastic pipe manufacturing industry

Rajoo Engineers JV with Bausano of Italy : plastic pipe manufacturing industry -

Vacuum forming machine with mould : model RECR 7086 XPS received and award Machinery for packaging operations from IPMMI IMDIR 2009.

Vacuum forming machine with mould : model RECR 7086 XPS received and award Machinery for packaging operations from IPMMI IMDIR 2009. -

Developed World's first ever four extruder five layer blown film and sheet extrusion system for Laboratory of Reliance industries

Developed World's first ever four extruder five layer blown film and sheet extrusion system for Laboratory of Reliance industries Launched India's first PS foam extrusion line and vacuum forming machine and exported to Ghana

Launched India's first PS foam extrusion line and vacuum forming machine and exported to Ghana Developed Asia's first ever four extruder five layer barrier sheet extrusion system with Unitilt polishing roll stack assembly

Developed Asia's first ever four extruder five layer barrier sheet extrusion system with Unitilt polishing roll stack assembly -

Entered into technical collaboration with Commodore Inc. USA for manufacture of XPS sheet line and thermoformer.

Entered into technical collaboration with Commodore Inc. USA for manufacture of XPS sheet line and thermoformer. -

Developed Asia's first seven layer blown film line incorporating Conical Spiral Stack(INCOSS) die

Developed Asia's first seven layer blown film line incorporating Conical Spiral Stack(INCOSS) die Developed Asia's first three layer wide width blown film line incorporating die dia 1200 mm and 4000 mm LFW with maximum output is 1200 kg/hr

Developed Asia's first three layer wide width blown film line incorporating die dia 1200 mm and 4000 mm LFW with maximum output is 1200 kg/hr Developed Asia's first ever 2000mm width physically foam sheet line

Developed Asia's first ever 2000mm width physically foam sheet line -

Developed Asia's first resin sack three layer blown film line and exported to Iran

Developed Asia's first resin sack three layer blown film line and exported to Iran Developed Asia's first seven layer blown film line and exported to Colambia

Developed Asia's first seven layer blown film line and exported to Colambia -

Awarded with GUJARAT GAURAV AWARD for its outstanding contributions to the plastic industry

Awarded with GUJARAT GAURAV AWARD for its outstanding contributions to the plastic industry Developed a CE compliance high ouput sheet line for processing rPET with 700 kg/hr and exported to germany

Developed a CE compliance high ouput sheet line for processing rPET with 700 kg/hr and exported to germany Became a STAR EXPORT HOUSE recognised by Government of India

Became a STAR EXPORT HOUSE recognised by Government of India Developed and supplied Asia's first sheet line for physically foamed PE sheets using carbon dioxide as blowing agent

Developed and supplied Asia's first sheet line for physically foamed PE sheets using carbon dioxide as blowing agent -

Launched Asia's highest output 3 layer blown film line with stack die(UCD) during Plastindia

Launched Asia's highest output 3 layer blown film line with stack die(UCD) during Plastindia Awarded Export Excellence Certificate from Engineering Export Promotion Council of India in recognition of highest exports during the year

Awarded Export Excellence Certificate from Engineering Export Promotion Council of India in recognition of highest exports during the year Asia's first 2 layer PPTQ film plant - 150 kg/hour

Asia's first 2 layer PPTQ film plant - 150 kg/hour -

Introduced India's first Electro-hydro-pneumatic plug-assist thermoformer with in-mould cutting for PP & PS containers

Introduced India's first Electro-hydro-pneumatic plug-assist thermoformer with in-mould cutting for PP & PS containers -

Introduced world's highest output TQPP downward extrusion blown film line at Plastivision 2002, christened AQUAFLEX.

Introduced world's highest output TQPP downward extrusion blown film line at Plastivision 2002, christened AQUAFLEX. -

Launched the India's first ever sheet line for PET at Plastindia

Launched the India's first ever sheet line for PET at Plastindia 5 layer stack die (UCD) with horizontal spirals - first time in Asia & 4th in the world

5 layer stack die (UCD) with horizontal spirals - first time in Asia & 4th in the world -

Rajoo Engineers Limited became an ISO 9001 certified company with further improved the Quality Management Systems. The Company has now graduated to ISO 9001:2000.

Rajoo Engineers Limited became an ISO 9001 certified company with further improved the Quality Management Systems. The Company has now graduated to ISO 9001:2000. -

Rajoo made a break-through and introduced its first plug assist, roll fed thermoforming machine, christened DISPOCON

Rajoo made a break-through and introduced its first plug assist, roll fed thermoforming machine, christened DISPOCON -

Introduced Internal Bubble Cooling(IBC) System for blown film lines

Introduced Internal Bubble Cooling(IBC) System for blown film lines -

Exported country's first CE marked machine to the European market

Exported country's first CE marked machine to the European market -

Introduced the first indigenously designed wide width blown film line for a lay-flat width of 3000 mm, christened MULTIFOIL

Introduced the first indigenously designed wide width blown film line for a lay-flat width of 3000 mm, christened MULTIFOIL Introduced the first indigenously designed extruder incorporationg grooved feed bush, barrier screw and cross-hole mixing section

Introduced the first indigenously designed extruder incorporationg grooved feed bush, barrier screw and cross-hole mixing section -

Introduced the first ever indigenously designed and developed Oscillating Haul-off System for blown film lines and displayed at Plastindia 1994.

Introduced the first ever indigenously designed and developed Oscillating Haul-off System for blown film lines and displayed at Plastindia 1994. Begun operation at Rajkot. Entered into a technical collaboration with a British Company. went public and the issue was over subscribed by nearly 24 times

Begun operation at Rajkot. Entered into a technical collaboration with a British Company. went public and the issue was over subscribed by nearly 24 times -

Rajoo introduced India's first ever Foamed PVC profile line and delivered to the pioneer in this field, M/S Trio Polymers, Junagadh

Rajoo introduced India's first ever Foamed PVC profile line and delivered to the pioneer in this field, M/S Trio Polymers, Junagadh -

Introduced the first Indian co-extrusion feed block for multilayer sheet line

Introduced the first Indian co-extrusion feed block for multilayer sheet line -

Launched the first ever blown film line to manufacture chemically foamed PE films

Launched the first ever blown film line to manufacture chemically foamed PE films Launched Asia's first ever EPE wad chemically foamed sheet line, christened FOMEX

Launched Asia's first ever EPE wad chemically foamed sheet line, christened FOMEX Made an entry into the International market with maiden export of a blown film line to Tanzania

Made an entry into the International market with maiden export of a blown film line to Tanzania -

Launched the first ever sheetline for HIPS, christened LAMINA

Launched the first ever sheetline for HIPS, christened LAMINA -

Launched monolayer blown film line, christened FOILEX

Launched monolayer blown film line, christened FOILEX Ventured into the manufacture of blown film lines and delivered first PPTQ blown film line.

Ventured into the manufacture of blown film lines and delivered first PPTQ blown film line. -

Commenced business as Rajoo Engineers Pvt. Ltd. at Manavadar, a small village in Junagadh Dist. to manufacture mechanical cutting-sealing machines

Commenced business as Rajoo Engineers Pvt. Ltd. at Manavadar, a small village in Junagadh Dist. to manufacture mechanical cutting-sealing machines

Awards & Achievements

Year 2024

On March 19, 2024, Rajoo Engineers Limited won the SIES SOP STAR 2023 award for PENTAFOIL-POD-AX, a five-layer blown film line for flexible packaging. Presented by the South India Education Society School of Packaging, Mumbai (SIES-SOP), the award recognizes excellence in import substitution and 'Make in India' initiatives, showcasing Rajoo's transformative indigenous technological advancements.

Ms.Khushboo Doshi , Managing Director - Rajoo Engineers Limited has been awarded "Nayee Pidhi Entreneure award -2024 " for her achievement as the icon for the new generation entrepreneur

Year 2023

Women Entrepreneur of the Year Award

Ms. Khushboo Chandrakant Doshi, Managing Director of the Company has been awarded the “Women Entrepreneur of the Year Award – Manufacturing Sector at the India SME Excellence Awards.

Year 2019

SIES Star Award-2019

On 8th February-2020,Rajoo’s MULTI-STATION THERMOFORMING MACHINE – DISPOCON-MS has been merited as “SIES Star Award-2019” In the Category “Packaging Machinery, Equipment’s & System” by SIES School of Packaging & Packaging Technology Center at Navi Mumbai(India)

Year 2018

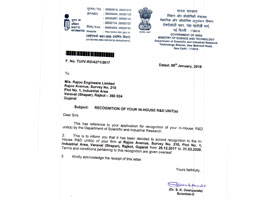

DSIR Certification

The Company received the 'DSIR' (Government of India) certification for its in-house R&D center named as 'Rajoo Innovation Centre

Rajoo Engineers' R&D center is dedicated to its customers with the objective of offering total and customized solutions to their clients in the field of packaging.

Rajoo Engineers Limited is felicitated as one of

The Best Plastics & Polymers Brands By The Economic Times Polymers on 7th March, 2018 in Mumbai.

A tribute to the founder - Shree Chandrakant N. Doshi.

Splendid dedication of Rajoo employees.

Thanks to all the stakeholders for their unstinted support.

Khushboo chandrakant Doshi was Felicitated with the Plasticon award as a Best Performing Female entrepreneur by Plast India foundation on February 7, 2018 in Gandhinagar

Year 2017

As Runner Up for 7th National Award for Technology Innovation in Petro Chemicals & Down Steamplastics Processing Industry (2016-17)

On 1st March, 2017, Citation presented in recognition of the contribution to technology innovation in the category of Innovation of Polymer Processing Machinery & Equipments for the Innovation in Woodplex - WPC Profile & Board Line " as Runner Up for 7th National Award for Technology Innovation in Petro Chemicals & Down Steam plastics Processing Industry (2016-17)

CNBC BAJAR & AKILA recognizes Rajoo Engineers for The Saurashtra Ratna Award in the category of "Struggle to Success to Story" The Award is bestowed on 8th April,2017 by Shree.Vijay Rupani, Hon.Chief Minister of Gujarat

Year 2016

Rajoo Engineers is recognized for as a Joint Runner up of 6th National Award for technology innovation in petrochemicals & downstream plastics Processing Industry (2015-16) for its contribution to technology innovation in the category of innovation of polymer processing machinery and equipment - Rajoo's Tilting Mould Thermoformer-Dispotilt.

The Award is bestowed on 20th January by Mr.Ananth Kumar, Hon.Minister of Chemical & Fertilizers, Government of India.

Year 2015

RAJOO has been chosen for the 7th Plasticon Silver Award for Innovative Plastics Processing Machinery & Ancillary Equipment (National). The honour was bestowed on Rajoo for its world's Smallest Three Layer Blown Film Lab Line - LABEX TM

Year 2013

August :

Late Shri Chandrakant N. Doshi awarded Lifetime Achievement Award in recognition of his contribution to the innovations in Plastics Processing machinery segment and to the global plastics fraternity by the CPMA & Elite Plus in the 2nd Speciality Films & Flexible Packaging Global Conference - 2013 held on 29th & 30th August in Mumbai.

June :

Late Shri C.N.Doshi awarded Indian Plastic Institute Award for excellent contribution to Polymer Industry in recognition of his outstanding contribution to Plastics Machinery Industry presented on 8th June,2013 at Mumbai.

Year 2011

Recognition of excellence for "Three Layer Lab-Line - LabEX Machine" in the category of "Machinery for Package Conversion" Presented at Mumbai on 23rd March 2012

Year 2010

Vacuum forming machine with mould: model RECR 7086 XPS received an award in "Machinery for packing operations" from IPMMI IMDIR 2009

Year 2004

"Gujarat Gaurav Award" for outstanding contributions to the plastic industry by Government of Gujarat

Year 2003

"Export Excellence Certificate" received from Engineering Export Promotion Council of India in recognition of highest exports during the year.